rfid technology in inventory systems From complete inventory visibility to maintaining stock counts, an RFID inventory system helps generate real-time access to inventory levels, stocktaking capabilities and . NFC Tag Reader & NFC Tools Writer is a simple and efficient application that lets you read .

0 · walmart rfid inventory system

1 · rfid warehouse inventory management

2 · rfid tracking systems for inventory

3 · rfid systems for small business

4 · rfid labels for inventory tracking

5 · rfid inventory tracking

6 · rfid for warehouse inventory

7 · pros and cons of rfid

Sensor Life. This is a clear win for the FreeStyle Libre 3. The Freestyle Libre 3 is rated for 14 days. The Dexcom G7 is only rated for 10 days (10.5 days, really, when you consider the 12-hour “grace period” for switching .

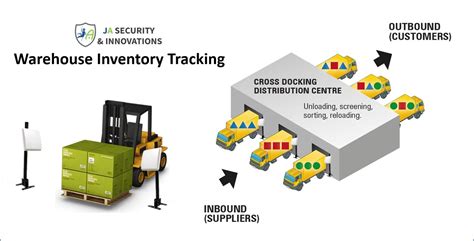

RFID Inventory Management is a system that leverages RFID tech for monitoring and managing items in your inventory. Adopting RFID injects speed, precision, and efficiency into your inventory tracking. It keeps you in the loop, registering every item’s exit or entry in real time.

From complete inventory visibility to maintaining stock counts, an RFID inventory system helps generate real-time access to inventory levels, stocktaking capabilities and .

walmart rfid inventory system

rfid warehouse inventory management

RFID Inventory Management is a system that leverages RFID tech for monitoring and managing items in your inventory. Adopting RFID injects speed, precision, and efficiency into your inventory tracking. It keeps you in the loop, registering every item’s exit or entry in real time. From complete inventory visibility to maintaining stock counts, an RFID inventory system helps generate real-time access to inventory levels, stocktaking capabilities and order/purchase summaries. RFID inventory systems help streamline and simplify the inventory process by eliminating manual counts.While there are many technologies aimed at improving inventory management, interest in radio frequency identification (RFID) has been growing across industries. Learn how, by using radio waves, RFID technology can track and manage inventory throughout the supply chain. An RFID (radio frequency identification) inventory management system helps with inventory visibility, particularly when using mass production. RFID technology can automate many inventory-related processes, such as stocktaking, reordering, and item tracking.

Radio-frequency identification (RFID) technology is a way for retailers to identify items using radio waves. It transmits data from a RFID tag to a reader, giving you accurate, real-time tracking data of your inventory. RFID technology allows you to see inventory quantities and movements, from groups or pallets, down to individual items. This makes the technology useful for: Supply chain management. Granular quantity tracking and inventory counts. Theft and loss prevention. Managing multiple locations or warehouses. End-of-day reconciliation of sales records. RFID systems make it a more efficient inventory management technology compared to traditional barcode scanning with its real-time visibility, reduced labor, better security, and longer read range. RFID technology can help reduce theft and unauthorized access to inventory. RFID readers can be placed at strategic points, such as warehouse exits, to detect and alert staff if items are being removed without proper authorization.

Radio Frequency Identification (RFID) is a type of technology that retailers can use to manage their inventory. It works by using RFID tags which contain electronically stored information, such as stock keeping unit (SKU) numbers, product prices, and stock levels. RFID technology is transforming inventory management by enhancing efficiency, reducing costs, and improving accuracy. As more businesses adopt RFID, it drives innovation in supply chain management, making it a cornerstone of modern inventory strategies. RFID Inventory Management is a system that leverages RFID tech for monitoring and managing items in your inventory. Adopting RFID injects speed, precision, and efficiency into your inventory tracking. It keeps you in the loop, registering every item’s exit or entry in real time.

From complete inventory visibility to maintaining stock counts, an RFID inventory system helps generate real-time access to inventory levels, stocktaking capabilities and order/purchase summaries. RFID inventory systems help streamline and simplify the inventory process by eliminating manual counts.While there are many technologies aimed at improving inventory management, interest in radio frequency identification (RFID) has been growing across industries. Learn how, by using radio waves, RFID technology can track and manage inventory throughout the supply chain. An RFID (radio frequency identification) inventory management system helps with inventory visibility, particularly when using mass production. RFID technology can automate many inventory-related processes, such as stocktaking, reordering, and item tracking.

Radio-frequency identification (RFID) technology is a way for retailers to identify items using radio waves. It transmits data from a RFID tag to a reader, giving you accurate, real-time tracking data of your inventory. RFID technology allows you to see inventory quantities and movements, from groups or pallets, down to individual items. This makes the technology useful for: Supply chain management. Granular quantity tracking and inventory counts. Theft and loss prevention. Managing multiple locations or warehouses. End-of-day reconciliation of sales records. RFID systems make it a more efficient inventory management technology compared to traditional barcode scanning with its real-time visibility, reduced labor, better security, and longer read range. RFID technology can help reduce theft and unauthorized access to inventory. RFID readers can be placed at strategic points, such as warehouse exits, to detect and alert staff if items are being removed without proper authorization.

rfid tracking systems for inventory

Radio Frequency Identification (RFID) is a type of technology that retailers can use to manage their inventory. It works by using RFID tags which contain electronically stored information, such as stock keeping unit (SKU) numbers, product prices, and stock levels.

rfid systems for small business

rfid labels for inventory tracking

rfid inventory tracking

rfid for warehouse inventory

Durable NFC & RFID Contactless Reader/Writer. The D600 seamlessly supports the widest variety of HF RFID and NFC devices under programmatic control. It has the same strengths and ease of use as our DuraScan barcode scanners: .Just dip or tap to pay. Be ready for every sale with Square Reader for contactless and chip. More customers than ever are paying with contactless (NFC) cards, and over 95% of cards processed through Square are EMV chip cards. Every dip or tap payment is the same simple rate: 2.6% + .

rfid technology in inventory systems|rfid for warehouse inventory